Laser microperforation for wood panels

ACOUSTICS AND DESIGN have a new partner

OT-LAS transforms environments with the new laser technology for micro-perforation of wood.

Maximum sound absorption, original aesthetics.

The new era of

wood microperforation

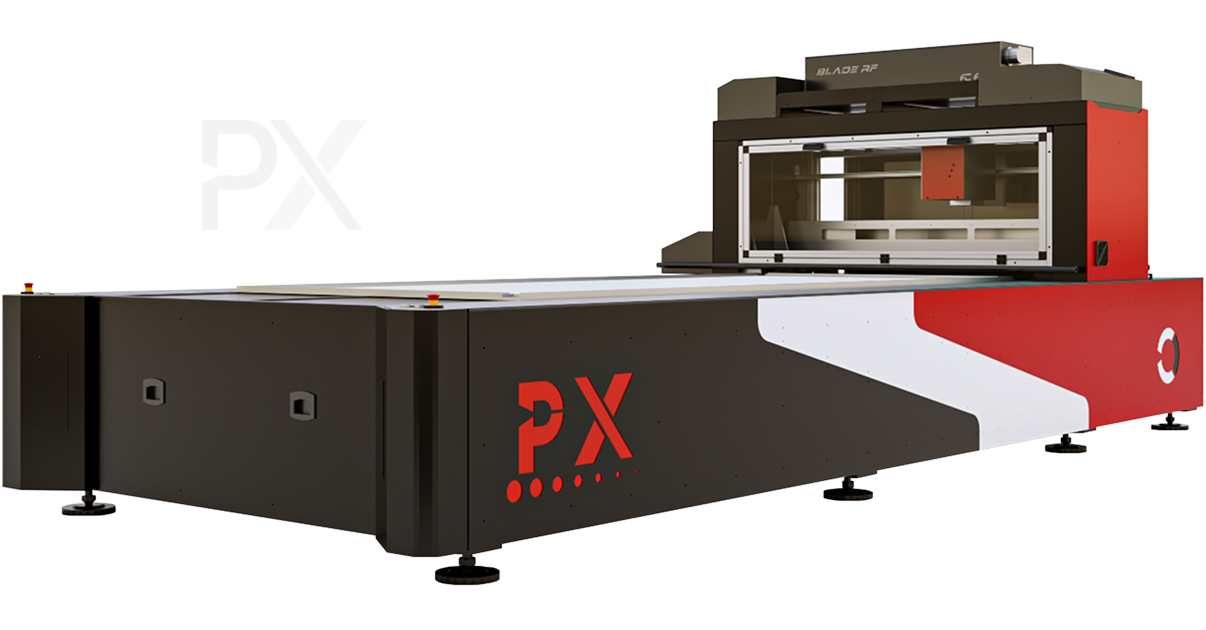

Laser woodworking is no longer limited.

OT-LAS’ new laser systems for micro-drilling sound-absorbing panels translate functionality into exclusive design. With absolute precision and infinite customization possibilities, OT-LAS laser machines protect the acoustics of public and private spaces with invisible textures or precious graphic effects. A new tool at the service of the harmony of environments.

The Made in Italy design

that conquers all the senses

Excellent sound absorption

The laser’s unbeatable precision offers outstanding sound absorption performance, with holes less than a millimeter in diameter, perfectly defined and evenly distributed over the surface. The result is a full control of the acoustics of the rooms, which protects from external noise with effectiveness and reliability.

High-profile aesthetics

OT-LAS laser systems allows unique micro-perforation for beauty and versatility. The micro-perforation of the wood gives life to refined geometries, sophisticated patterns and imperceptible textures. The accuracy of the creations also lends itself to the cladding of classy environments, such as theatres, hotel lobbies and design interiors.

Minimal environmental impact

Laser micro-perforation of wood protects the environment and workers thanks to its distinctive green technology. In addition to not requiring chemicals and pollutants, laser processing reduces the risk of material damage due to the absence of mechanical tools in the engraving or microperforation process. In addition, the laser’s extreme precision reduces processing waste and waste production. In addition to these advantages, there is a reduced consumption of energy resources compared to traditional technologies, guaranteed by the production efficiency of OT-LAS laser systems.

FROM WOOD

to custom interior design

The wood takes voice

Made of high-quality wood, it is transformed into key elements of environments that combine aesthetics and acoustic comfort. Ash, oak, birch: each essence brings with it a material history made of veins, warmth and texture. This is where the process begins: from respect for the matter and the vision of what it can become.

Design without limits

Organic textures, bold geometries, subtle textures: the design takes shape through a map of micro-holes designed not only for acoustic performance, but also for the look. Designers, architects and acoustic consultants can now rely on custom patterns that combine charm and performance. Each project is a creative workshop, where laser technology is put at the service of the final work.

Laser microperforation

The OT-LAS laser systems perform microperforation with extreme precision, creating holes invisible to the eye but powerful in effect. The laser technology allows a contact-free processing, which protects the surface of the wood and guarantees impeccable detail even on the most complex textures. This is where the material becomes a sound-absorbing surface, without ever renouncing elegance.

The result that makes space

When the micro-perforated panel is ready, it is no longer just a technical element: it is a distinctive feature of the design of the environment. Reflects light, absorbs sound, speaks the language of the final project. In theatres, offices, hotels and homes, laser-processed wood tells a new harmony between function and form. A silence cared for, a design to listen to.